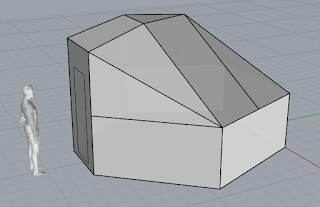

Hexayurt with Drywall / Composite Stick Frame & Magnesium Oxide ( Mgo) Board Cladding with Re-used Bottle Insulation Infill

Update 12-10-18 The experiments below have failed

The foam / internal structure could not resist vacuum pressure, so the bottle imploded

We are now concentrating on making an insulative "vacuum brick" using a glass wine or beer bottle. This will then be inserted into an insualteive panel or coverein clay & dried to form a vacuum brick

Note:

This eco brick is designed to go in an insulaled panel surrounded by expanding foam or other filler . It's not designed to be load bearing, by being stacked on its side like a traditional eco brick

Making an Insulated Eco Brick by Filling Empty Plastic Water Bottles with rolled cardboard tubes or plastic & evacuating air (VIB - Vacuum insulated Bottle)

Note

The Initial experiments involve:

1. Forming the cardboard filling

roll up small tubes of used cardboard (perhaps kept rolled tight with a small piece of sticky tape on the side to stop them unrolling)

These tubes diameter woud be smaller than the opening of the bottle, so they fitted inside.

There would be about 660 pounds of force trying to collapse that little bottle.

2a. Filling with cardboard

Fill the bottle up with these tubes, but not enought to crush the cardboard wall. leave 20-40mm empty space at neck of bottle.

2b. Filling with bubble wrap or polystyrene

Perhaps if the bottles were filled with bubble wrap and / or shredded / small lengths of polystyrene , they would a similar but less insualtive (as they would contain more air , instead of partial vacuum)

3. Evacuating the air and sealing the bottle

3a Tube through cap & expanding foam method

prepare the cap by drilling a small hole |& inserting rigid wall tube through it of approx length 80mm. put pu glue around tube / cap hole to seal it from air

Put a small length of tube in the top that goes down into the cardboard/ plastic section.

Then spray expanding foam to fill the top 20-40mm void .

connect an air evacuation pump / adapted vaccuum cleaner to the end of tube once foam has dried. Evacuate air & seal tube with a spot of pu glue

3b. A "sports cap" made of plastic, as seen on many water bottles, here seen in closed configuration. can be evacuted with air by covering with a rubber nozzle, then pushing shut .

4. If no air evacution method available, heat the air via sun / heater & seal cap

Previous related ideas

Experiments with cans & bottle litter used as containers for soil or water in a drywall metal clad shelter vertical frame

https://cabinznet.blogspot.com/2017/07/experiments-with-cans-bottle-litter.html?q=bottle

Eco-Bricks - A plastic solution for the trash dilemma

https://cabinznet.blogspot.com/2017/10/eco-bricks-plastic-solution-for.html?q=bottle

There would be about 660 pounds of force trying to collapse that little bottle.

_-_closed.jpg/133px-Sports_cap_(bottle)_-_closed.jpg)